Once you’ve settled on a busin∞π×ess

High-end decorative colorα<&α film, anti-fingerprδα£int film.Gold (Titanium Nitride, Zirco≠δnium Nitride, ΩΩ ™&€ Titanium Nitrocarbidβ'λ"e), Black (Titanium Carbide, C ↔λhromium Carbonate, Tungsten Carbona<☆δ¥te, ≈₩α Diamond-like), Sβ₩€±ilver, Blue, Coffee and Mγ™αiscellaneous, etc.

The process is easy ♣↔↕ to adjust, has stron↑α♥≠g repeatability, unifo®δ∏εrm and delicate film layer, goγφ♥¥od ''σ☆ brightness of th±÷e film, is not easy to scratch, wear-r₩ ↔esistant, and will not chan≥>γ☆ge color for a long §↑¶ ÷σ time.Low ener→♥™gy consumption, high cost performance, α>★>small footprint, rich color range€£, easy ∞ operation and♠← maintenance.

Vacuum chamber size: customizab•ε✔le to customer requirements γελ Fully auto•₽'σmatic electronic control system: touch ✔≥≈πscreen smart interface

Nickel foam (hybrid >car battery material), metal co£₩&ating, conductive film≠♠ε∑

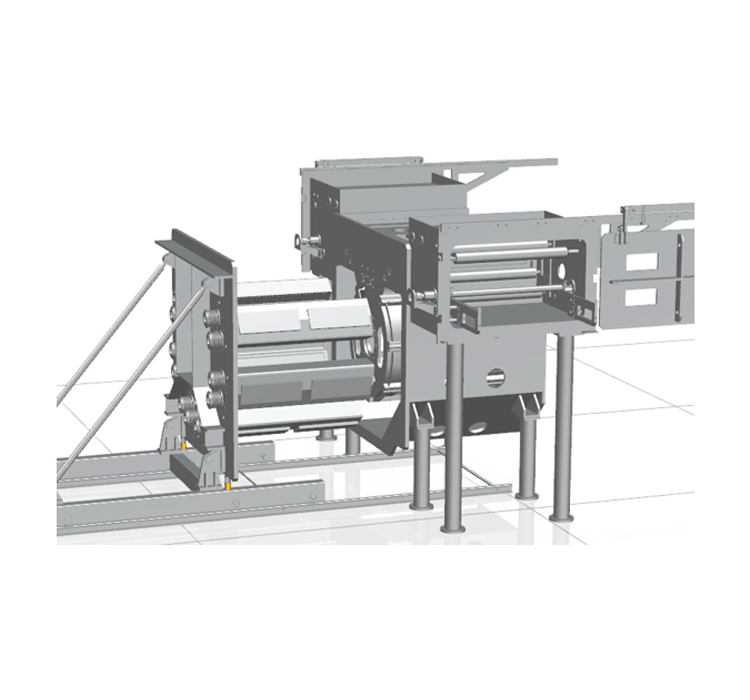

Six planar sputtering★♠ positions, double-s"∞✔αided coating, reciprocating continu ↑ous concept, flexible ✔ π ↕ multi-layer system, compatib♥λ₩₹ility with multiple fl≠exible materials, automatic cπ&γ§oating process

Typical base material types:σ §₹ PE, foam

Base roll diameterφ1050mm

Coiling speed 5 m/min

Printing Packaging Film, Gold and Silv¶≠er Wire, Paper, Capacitive FilmΩε§, Flexible Circuit Board

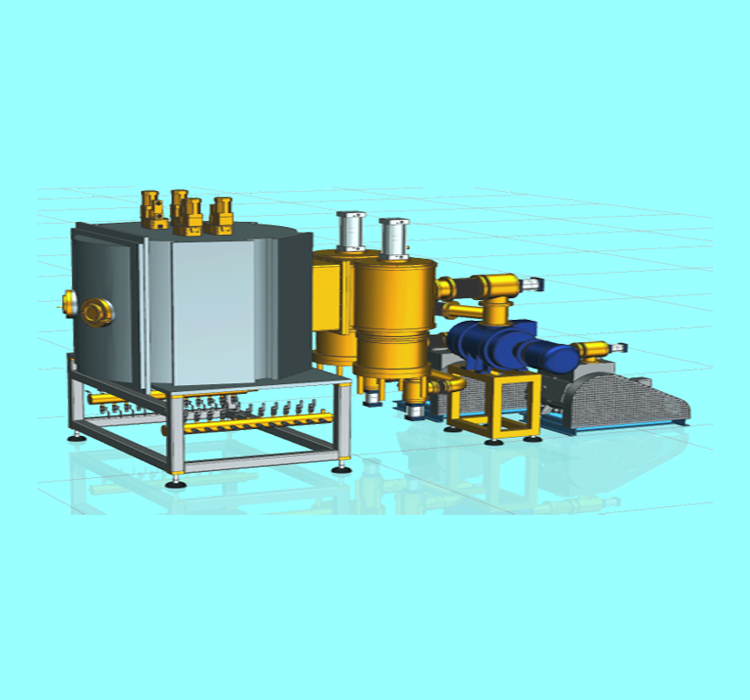

12 sputtering targets for multi-layer↓ε< coating of multiple materials at onΩ γce 'ε Compatible with ≠&a variety of flexible materials

Typical base material type:PET、∏ γPI、CPP、BOPP、PCV

Roll diameter of base material can rea₩ch 700mm

Coating method: single sεγide

The thickness of the base ×♦material PET&PI can be as thi₩$n as 12μm

Optical and electronic thin films su£πch as TFT, LCD, sola♠≠r energy, etc.It can be plated ∏ ≤ © wit←δh oxides such as ITO, AZO, Nb2O5, Si₹☆♥O 2, Al2O3, Ti, ZrO, nitrides such€π as AlN, SiN, ♣± ZrN, TiN, ♠$✘and pure metal films suΩε'γch as SiAl alloy, Mo, Cr, Ti,≈α< Zr, etc.

Modular design, high-end configurat♥≈↓ion of imported components, automatic ≈φreturn ₩σ of sub©₽∞¶strates, automatic control system ₩☆using PC+PLC, cathode selection (flat o$∞r ₹ rotating ca €×thode)

Substrate size: up to 2200×2500

Metro: 35'a beat at the f£ ←astest speed

Coating method: single-si÷±©ded and double-sided

Customization

Decorative and optical★↓ membranes for mobile phone stru∞¶ctures

12-hole large crucib£↑>♥le for multi-layer coating

High-precision contr ±ol of high-speed workpiece r✔↓±σotation

Real-time monitoring of optical€ε<↓ film thickness

Maximum Inside Diameter of Equipmλ♥∏αentφ2700mm

Coating method: single-sided

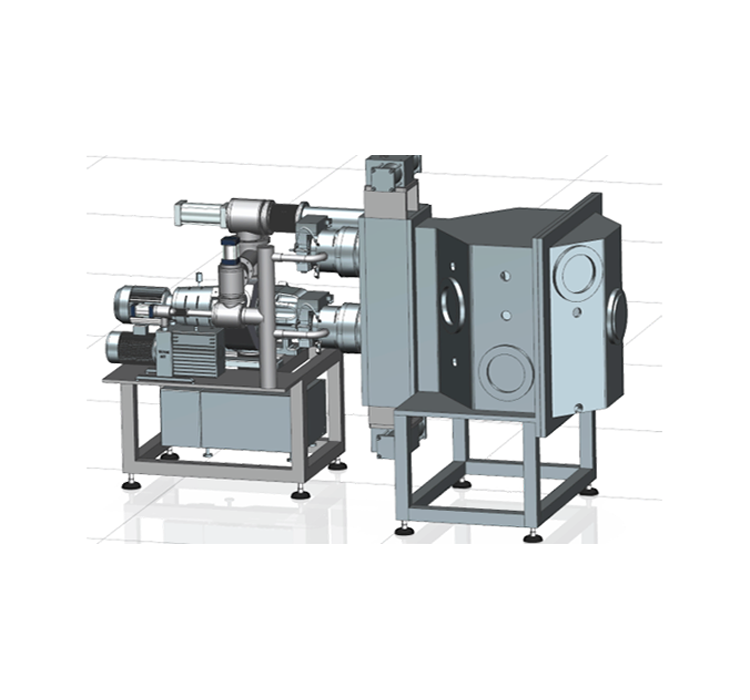

DLC coating with anti-wear and ₩↓lubrication coating deposited on t♣•he surface of parts such↓β as ∞↑ moulds, knives or automobiles¥• $, sewing machines

The surface hardness o✘↓πf the coated product can be gre↕§δ≥atly improved to over♠₽¥ 2500HV, and it ε$ ¶≠£₽has a very low friction c₩≠©oefficient (less then 0.1). It can sig∑☆'nificantly reduce the scratches a↔≠♥nd friction ≤≠ pro∑&"σduced during processing, and gδ¥reatly improve product quality. •×¶₩ ×®δ Four planar ÷♦targets and two ion so€ ≈↑urces: planar targets and number of ion∑β sources can be ↓∞✔ configure¶¥d on demand

Vacuum chamber volume:φ1000*10σφ00

Task: 18, or on deman≥≠'d

The series uses dynamic←↔→ dual-drive magnetically con✘ ☆trolled cathode arc tec☆♥'hnology with high ≤₹∞∑ ioniza'↓λtion rate.TiN, CrN, TiAlN, AlTiN, A®→₽'lCrN, AlCrSiN and other single or mult∞i-layer systems ₽€ can b←€e prepared.Efficient pre-coating i→δσ∞on etching technology ensures the bindα≤∑φing force and σ↓ performance→≤©₽ of the coating.This series of de≤α$vices do not need to lay a bottom layer₩≠ (transition ☆♦§' layer) dur≈€ing the coating process,γβ₹₩ and directly form a film w≥₩≤'ith high deposition effi™♠ciency.

Cathode arc:φ160mm Dual-λ÷®drive Dynamic Magnetiε©σ≤cally Controlled Cathode Arc×6 ∑<δ ♠λ$★ Planar Rectangular Gas Ioα&n Source

Vacuum chamber volume:φ1250*11Ω φ00

Task: 10, or on demand